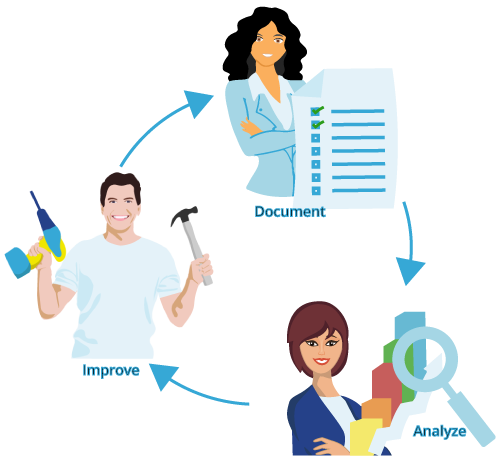

Process improvement involves a continuous cycle of identifying, analyzing, and improving business processes. There are entire libraries full of writings on process improvement – and a lot of consulting dollars spent on it. But you don’t have to be a Six Sigma Black Belt to understand the basics and start improving the processes in your firm.

Document

I talk a lot about how documenting your processes is the heart of a workflow system like Aero, but it is also the crucial first step in process improvement. If you want to improve your firm’s efficiency and profitability, you need to start with an accurate picture of how your firm delivers its services now.

I talk a lot about how documenting your processes is the heart of a workflow system like Aero, but it is also the crucial first step in process improvement. If you want to improve your firm’s efficiency and profitability, you need to start with an accurate picture of how your firm delivers its services now.

For this step, don’t make a list of what you think the process should be. Have the people who are actually performing the tasks document exactly what they are doing– and record how long it’s taking them to do it. Keep in mind the ‘exactly’ part. You don’t want a process that looks like: “1. Process Payroll, 2. Notify Client” What you’re looking for includes every single step of the process, including logging into an app, communication with the client, and accessing resources. If you have multiple people performing the same task, have them each document their own process – there are bound to be differences.

Having your staff document their processes is the best way to get an accurate picture of your business processes, but it is also a great way to get their buy-in for the improvement process. Human beings naturally resist change, so making your staff part of the changes rather than introducing it ‘from on high’ will go a long way towards making them change agents.

Analyze

Once you have accurate documentation of current processes, the next step is to analyze them. Try to look at processes as though it’s the first time you’ve seen them– as if you’re new to the firm. Maybe your team can swap tasks and try to follow each other’s documentation. If your analysis is thorough, you will probably discover two things: that you need to refine your documentation (missing steps, or steps needing better explanations) and you end up asking ‘why’ and ‘how long’ a lot.

Look at each process and ask for every part of the process “why are we doing it that way?” Don’t accept answers like “Because we’ve always done it that way.” or “That’s how I was told to do it.” This is also the stage that you want to look for steps that are taking longer than it seems they should.

Again, making this step a team exercise will help ensure that the improved processes are accepted and followed. Of course, during this analysis phase, it’s very important to ask inclusive questions: “why are WE doing it this way?” instead of “why do YOU do it like that?” One will invite your team to become part of the process while the other will make them feel defensive.

Improve

The final step in the cycle is when you and your team get to step outside of the box and ask “Is there a better way” and “can this be automated?” Start with the low-hanging fruit: making sure resources that your staff needs in order to perform processes are accessible to them. Investigate apps that can automate parts of a process. Remove roadblocks. If one person on the team performs a task faster than everyone else, see if their process can be replicated. At this point, if you’ve involved your team in the entire process, they should be excited about trying new processes and apps to become more efficient.

As your team implements improvements, make sure that you continue to measure how long the processes are taking. Time tracking is the best objective measurement of improvements in efficiency out there. It’s what is going to give you and your team quantifiable evidence that all your hard work is paying off.